Offshore electricity substations were one of the key topics that experts focused on during the first “DNV Technical Seminar on Electrical Systems for Offshore Wind”. Experts from DNV and Semco Maritime presented the subject of design, verification and certification of offshore power substations in offshore wind farm projects.

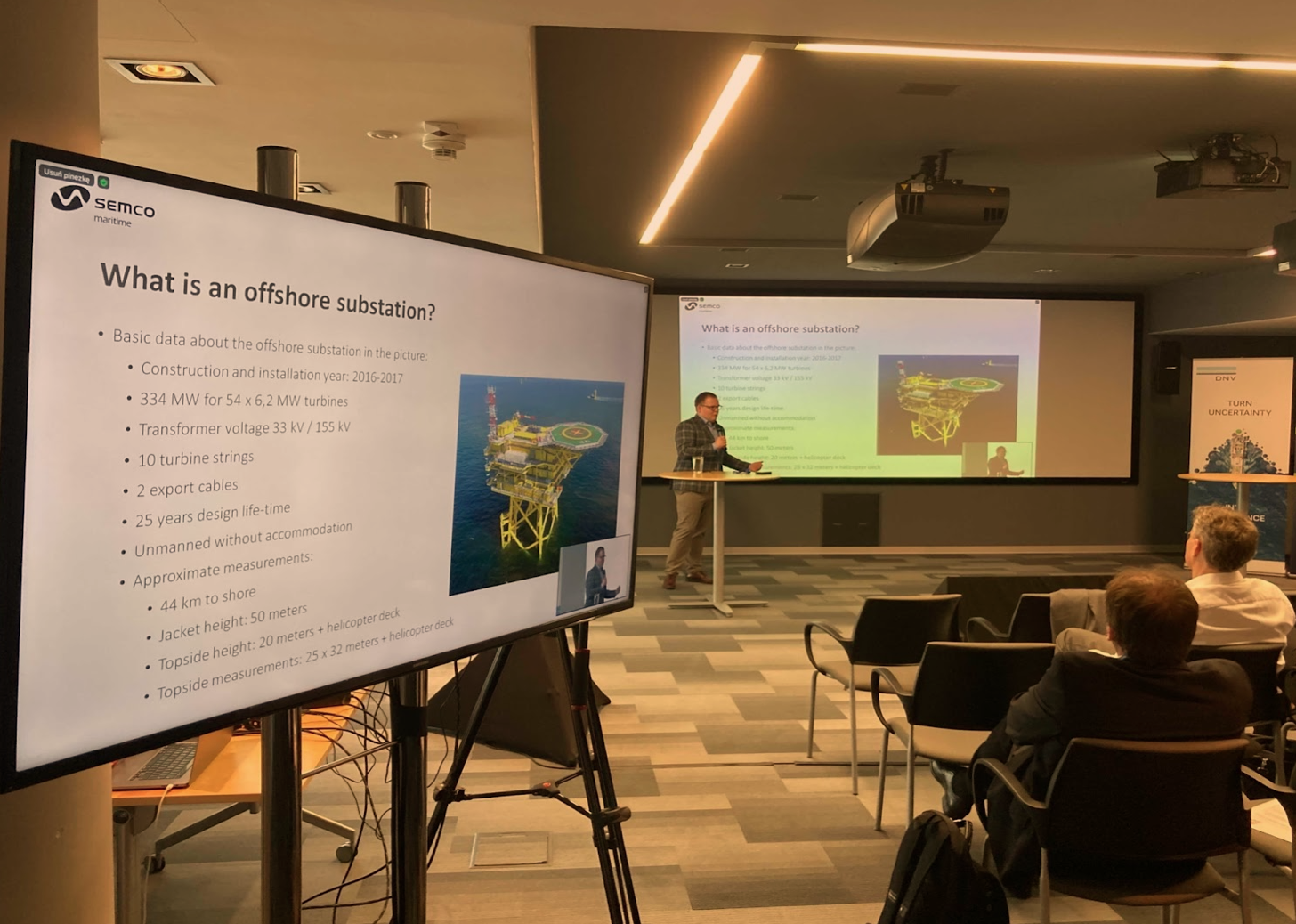

Anders Sølbæk, Lead Electrical Engineer at Semco Maritime, responsible for Semco Maritime’s operation in Poland, emphasized that the company’s branch – Semco Maritime already has over 20 years of experience in the field of construction and design of marine substations, created in the turnkey formula or with elements of the EPCI formula (Engineering Procurement Construction Installation). Currently, the industry designs offshore reactive power compensation substations, transformer substations and AC/DC converter substations. Over the years, substation technology has also changed. The first Vindeby offshore wind farm project in Denmark (1991) did not include any offshore substations, while the Hornsea Project One offshore project (2019) requires three offshore substations. Sølbæk discussed examples of specific substations (e.g. in Germany) and the diagrams of offshore substations’ functioning in the case of high, medium and low voltage.

During the seminar Jacek Albrecki, Principal Approval Engineer at DNV – Maritime, also discussed the process of verifying an offshore substation on the example of the SylWin Alpha Offshore HVDC converter platform installed in German waters. The substation includes 240 wind turbines with a total capacity of 864 MW.

DNV has developed standards for the design of marine substations (DNV-ST-0145). The standard can be used to design the construction and operation of offshore substations. The study contains requirements for areas such as structural design, safety, rules for arranging devices or responding to emergency situations.

Offshore platforms are a key element in connecting the offshore grid to the onshore power system. Their main task is to collect energy from wind farms, increase the voltage and transfer the energy to land. Due to their function, platforms are divided into two types – collector platforms and HVAC and HVDC export platforms. The former, as an intermediate element in the offshore infrastructure, is located between the wind farm and the main offshore substation. The HVDC platform is usually located a short distance from the offshore wind farm to facilitate the connection of other plants and the transmission of energy over a single HVAC or HVDC link.

Markus Kochmann, Head of Section for OSS at DNV – Renewables Certification, presented the certification process of marine substations. Kochmann was also involved in the development of the DNV-ST-0145 standard.

– Now, we see that international projects use DC connections, e.g. in the British Dogger Bank wind farm and on the US East Coast. There, we exceed 1 GW in individual installations and projects with a capacity of 2 GW are on the horizon. The direction aiming for the large-scale platform is therefore clear, said Kochmann.

However, works on AC platforms, in particular with a capacity of up to about 700 MW, are also noticeable.

Kochmann also described the requirements for offshore substations on the Polish market. The main document regulating the development of offshore wind farms is the Act of 17 December 2020 on promoting electricity generation in offshore wind farms. As far as certification is concerned, the key is, amongst others, an amendment to the Act on Maritime Safety of 29 July 2022 and theAct on Maritime Areas of the Republic of Poland and Maritime Administration. Certification is mandatory by law. In Poland, there are three stages of certification that confirm: Design Compliance, Commissioning, and Operation-Safety Certificate. The international project certification system, widely used in the industry, is contained in the documents IECRE OD-502: 2018 and DNV-SE-0190: 2021